Mechanical Test Fixtures

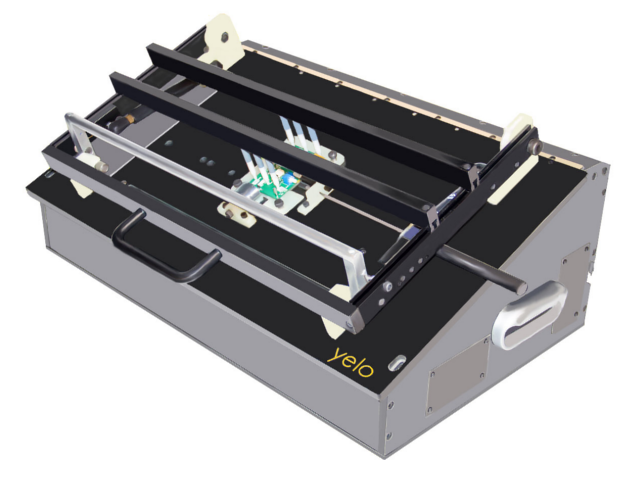

The Yelo mechanical fixturing system is designed for lower probe count applications. This can be for smaller PCBs or for larger boards where 100% probe access is not required such as for funtional testing. Functional testing typically requires only 10% of the nodes to be accessed by probes.

Yelo fixtures have a repalceable probe plate, which allows most of the fixture to be reused for new products resulting in savings in on-going fixture costs.

This is a very low cost bed of nails fixture and can be supplied in kit form, to wire yourself, or as a completed turn key feature.

Yelo fixtures have a repalceable probe plate, which allows most of the fixture to be reused for new products resulting in savings in on-going fixture costs.

This is a very low cost bed of nails fixture and can be supplied in kit form, to wire yourself, or as a completed turn key feature.

Affordable fixturing solution

Replaceable probe plates to reduce new product costs

Available as kits for in-house drilling and wiring

Full customisation available

Suitable for products with surface mount components

Fixtures can be used stand alone

Interested in getting a quotation or some more information?

Key Features

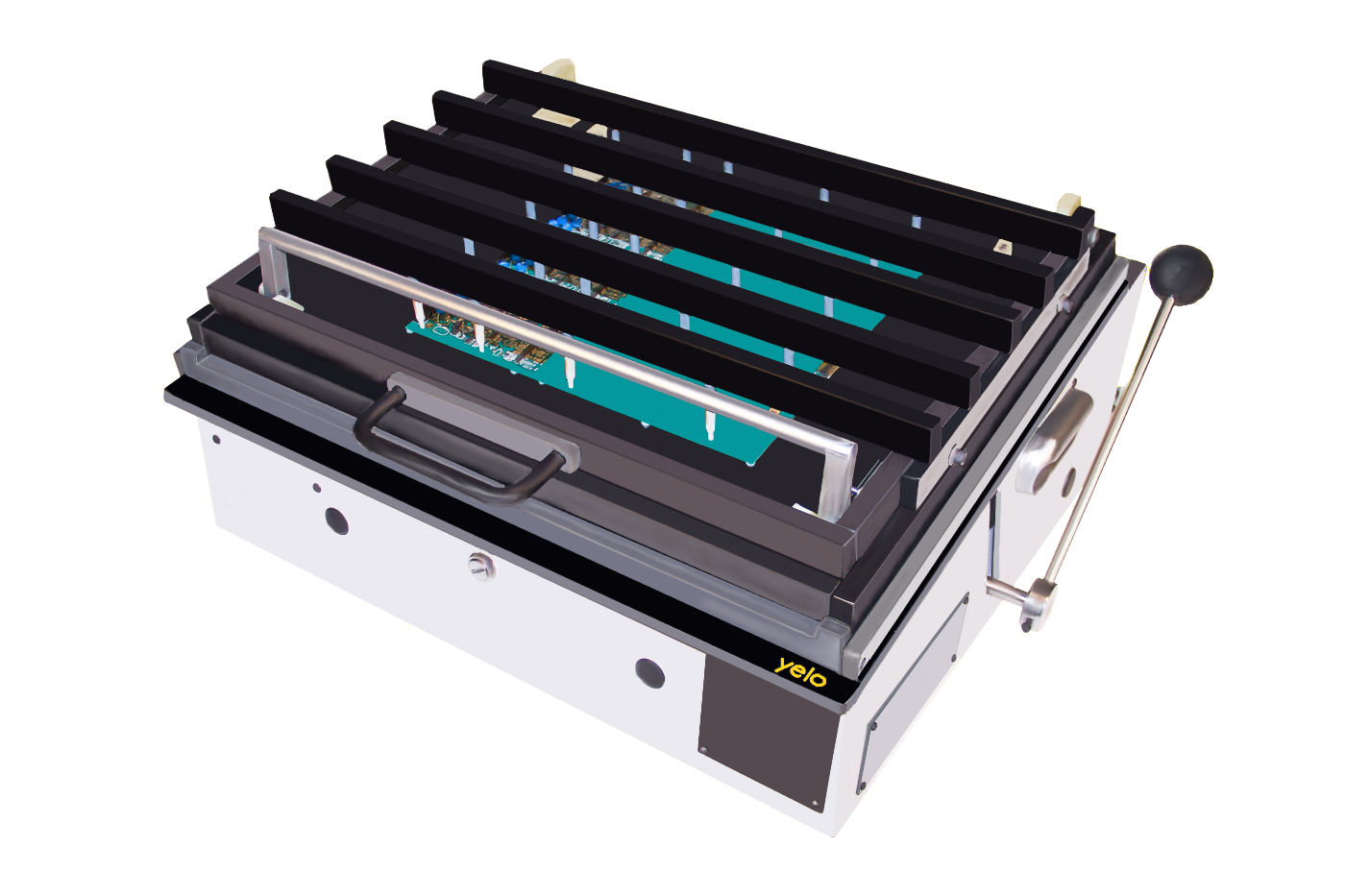

Yelo mechanical fixtures have an open lid also known as a top hat. The PCB is placed onto a sub-pate just above the probes and the operator shuts the top hat. This action pushes the PCB down onto the probes. The sub-plate ensures that the PCB does not rest on the probes and since it is spring loaded, the PCB moves down evenly.

Key Features

Yelo mechanical fixtures have an open lid also known as a top hat. The PCB is placed onto a sub-pate just above the probes and the operator shuts the top hat. This action pushes the PCB down onto the probes. The sub-plate ensures that the PCB does not rest on the probes and since it is spring loaded, the PCB moves down evenly.